Minimum order quantities are determined individually, taking into consideration the composition of the supplement and its form. We have a flexible production minimum, adjusted to the needs of launching the brand on the market.

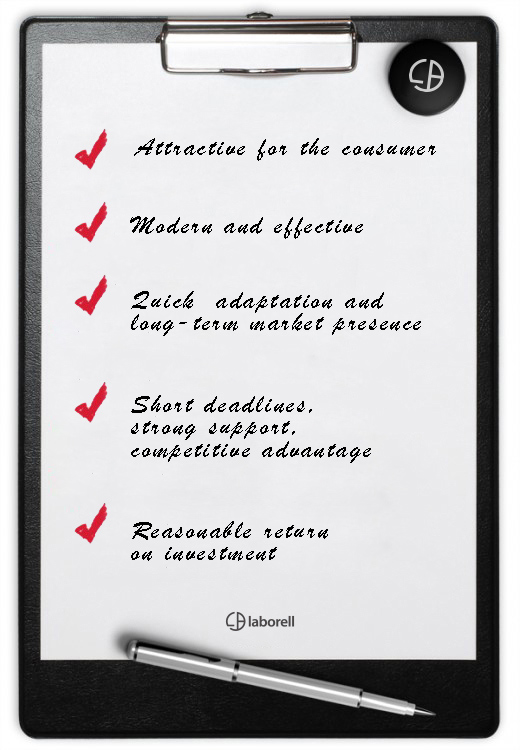

THIS IS HOW BESTSELLERS ARE MADE

The list of clients' expectations is always long and challenging. That is why we are constantly looking for, studying scientific studies, analysing research results.

We're in the range of our interests:

- consumer markets in Poland and all over Europe (communication, concept, loyalty, segmentation, satisfaction)

- modern technology,

- raw material offers and all related scientific research,

- advertising concepts, strategies for creating a leading brand,

- requirements and legal regulations applicable in Poland and Europe,

- and, of course, cost structures, resource efficiency and profitability accounts.

Knowledge, experience and passion make us ready to create bestsellers on request.

Laborell

We have a hunch about the trends

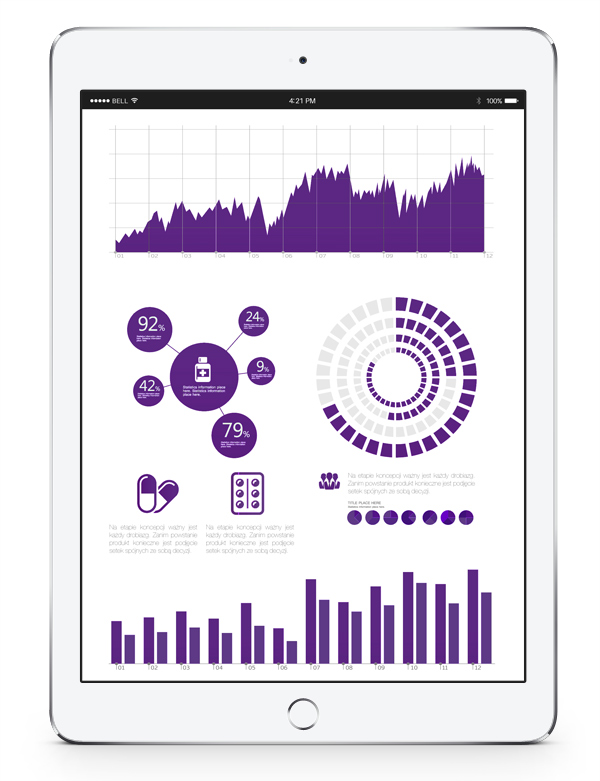

Every little thing is important at the concept stage. Hundreds of consistent decisions need to be made before a product is developed.

- Choosing the right market segment with the right purchasing power and motivation to buy...

- Defining the needs of customers, looking for free space in the market...

- Developing a product concept - scope of action, advantages for the consumer to purchase, form, smell, colour, price, method of distribution...

- Conceptual sketch of the future brand - form, colours, promotion channels...

The goal is an ideal product that meets customer expectations, i.e. market success.

Documentation

We constantly monitor and update the legal requirements for dietary supplements. At each stage of the project, we prepare complete documentation and represent the client in all necessary institutions throughout Europe. We also develop substantive documentation on the scope of the dietary supplement. Product documentation for dietary supplements

Storage and transport

Storage and transport always take place under thermal control conditions, in accordance with the requirements of the Act of 6 September 2001. Pharmaceutical Law and the Regulation of the Minister of Health of 26 July 2002 on Good Distribution Practice Procedures.

All the subcontractors selected by us also comply with the above conditions.

We know how to bring a product to market in record time.

Experience, working systems, parallel collaboration between all departments, a personal supervisor and several internal Laborell secrets make up our successes and records in bringing products to market quickly.

Fast and efficient, but with due diligence, because quality is above all.

Assistant

In order to facilitate and streamline the implementation of the project, we provide a personal supervisor for each of our clients.

A personal supervisor coordinates all Laborell departments, at all stages of the project.

However, his most important task is to work closely with the client. It is extremely important to us that the cooperation with Laborell is as simple as possible for our customers. We also want the project to meet all customer expectations.

If you intend to launch a new dietary supplement on the market or want to improve an existing product, your personal Laborell consultant invites you to contact us.

Ask for an offer

ask@laborell.com

Tel: +48 666 986 404

If you have any questions, want to know about the subject or need help in marketing dietary supplements. We will be happy to help you.

Wide range of products and services

We produce dietary supplements, cosmetics and dietetic food. We offer various forms of manufacturing of these products:

soft capsules, hard capsules, pouches, powders, liquids, food

Dietary supplements

Laborell has a modern machine park. Thanks to this, we provide a wide range of packaging matching the product form. The products are packaged in:

sachets, blisters in any shape and size, containers, HDPE, PE, glass bottles, vials, tubes, boxes, cans, jars

Packaging of food supplements

We offer shrink sleeve labels. The characteristic feature of these packages is that they take the shape of the packaging on which they are used - even with very irregular shapes.

Laborell also offers services of product packaging in the field:

contract packaging, sleeving, labelling, packaging filming (duopack sets)

Branding food supplements and cosmetics

We help to create a name and design the brand's visual identity (logo, sign book) and packaging.

Laborell offers marketing and graphic support. We support our customers during the creation of brand strategy, using all data collected during the first stages of product development. We are aware that the key and last link is the product's recipient (consumer), who decides about the brand's success.

Contract manufacturing of cosmetics

We offer the highest quality cosmetic products (creams, gels, lotions), detergents (shampoos, shower gels, bath oils), and medicinal products.

We provide comprehensive support - development of formulas and technologies for the production of cosmetic products, contract production, packaging.

Natural supplements for animals

Laborell VET is a contract manufacturer of supplements and animal feed additives. We create products perfectly suited to special dietary needs.

Supplements can come in various forms (lozenges, powders, flours, capsules, granules, pastes, liquids, drops, sprays, chews). We produce both vitamin and mineral-vitamin preparations as well as multipreparations - containing several active substances.

If you intend to launch a new dietary supplement, veterinary supplement, athletes' product or want to improve an existing product, please contact us.

CONTRACT MANUFACTURING

MANUFACTURE OF FOOD SUPPLEMENTS and COSMETICS

Laborell is a reliable manufacturer of dietary supplements, a manufacturer of cosmetics, a manufacturer of veterinary supplements and food and sports nutrition products.

Process

-

Formulation

-

Production

-

Confection

-

Samples

-

Packaging

-

Labelling

-

Documentation

-

Registration

5 steps to your own supplement

Laborell offers its customers various models of cooperation. One of them is contract manufacturing of dietary supplements or cosmetics. It consists in the comprehensive execution of a production order, which in short includes: product concept, formulation development, selection of formulations, preparation of registration documentation, production, packing.

1 Product concept

Laborell implements a concept or develops a product idea to order. The product should be unique and meet the needs of the customers to whom it is addressed.

At this stage, the supplement's area of operation, the product's target group, manufacturing cost, initial marketing and sales communication, as well as the colour, smell, form of product administration and methods of marketing (sales) implementation are defined.

2 Product recipe

We develop a product recipe that ensures the planned scope of operation of the supplement. At this stage, we also select the best form of administration (tablet, capsule, sachet, liquid) and plan the production process.

Then we examine the market and verify the availability of raw materials. All raw materials used in the production of dietary supplements, regardless of the country of origin, are checked and must meet the quality requirements specified by law.

3 Product branding

On the basis of production documentation, we develop a marketing strategy, i.e. we define the target group, develop a method of communication, prepare packaging design and possible promotional materials. We know that packaging sells the product, so we help to create an attractive and recognizable brand.

4 Production

The production stage is carried out under the watchful eye of our specialists. The production of dietary supplements, cosmetics and food is subject to meticulous quality control. All ingredients used in the production of supplements come from reliable suppliers. The Microbiological Quality Management System implemented at Laborell requires microbiological risk assessment already at the stage of laboratory product development. We subject all raw materials introduced into production to microbiological analysis. The first production batches are also subject to microbiological assessment.

We make sure that every employee involved in the process of manufacturing and transporting the product knows and applies appropriate procedures, understands the validity of their implementation and is aware of the responsibility for the implementation of the production safety and hygiene policy.

5 Placing on the market

At this stage we prepare the necessary product documentation. We also perform tests of finished products according to the principles of Good Laboratory Practice (GLP), which are a guarantee of reliability of the obtained results and correct archiving of test results. Finished products receive appropriate certificates.

The finished product is stored and ordered for transport. Quality control relates to the processes of storage and transport, starting with proper packaging, protection and description, through storage and transport in fixed temperature ranges suitable for dietary supplements.

Storage and transport always take place under thermal control conditions, in accordance with the requirements of the Act of 6 September 2001. Pharmaceutical Law and the Regulation of the Minister of Health of 26 July 2002 on Good Distribution Practice Procedures.

Raw materials from reliable suppliers

All raw materials used in the production of food supplements, regardless of the country of origin, meet the requirements set by the Laborell Scientific Council. Each supplier recommended by Laborell is checked for the quality of the offered raw materials.

Microbiological analysis

The Microbiological Quality Management System requires microbiological risk assessment already at the stage of laboratory product development. All raw materials introduced into production are subject to microbiological analysis. The first production batches are also subject to microbiological assessment.

Quality control

In the production process of food supplements, meticulous quality control is an elementary requirement.

All ingredients used in the production of the supplement come from reliable suppliers.

The custom of high and reasonable requirements also applies to intermediate production (capsules, blisters, boxes, bottles, etc.).

The entire manufacturing process of the product is carried out in accordance with the requirements of international standards.

We fill in the Microbiological Quality Management System

Tests of finished products are carried out in accordance with the principles of Good Laboratory Practice (GLP) ensuring the reliability of the results obtained and correct archiving of test results. Finished products receive appropriate certificates.

The entire logistics system meets the requirements of Good Distribution Practice

Quality control covers the entire process of storage and transport, from proper packaging, protection and description to storage and transport in fixed temperature ranges suitable.

Proven procedures

Every employee involved in the process of manufacturing and transporting the product is familiar with the relevant procedures, understands the validity of their application and is responsible for implementing the health and safety policy of production.

We take care of sustainable development and we give up activities that may have a negative impact on the environment.

The questions that our customers most often ask

If you need any information or have not found what you are looking for in our FAQ, please contact us:

ask@laborell.com or call + 48 888 955 545

-

What are the minimum order quantities?

-

How does the registration of documents and application to GIS look like?

On our side is to prepare full documentation on production and product registration. We also prepare comprehensive documentation for export markets together with Free Sales Certificate and other necessary documents, which are necessary to register a given product in a given country. We also deal with the registration of your products in GIS and provide full service in case of responses to letters from GIS.

-

What is the difference between a hard capsule and a soft capsule?

Hard capsules are containers consisting of two previously produced cylindrical parts which are rounded and closed on one side and open on the other. The hard capsules can be filled with powdered substances or solid particles, e.g. pellets, miniticaps, microcapsules, or they are filled with a paste consistency. Filling is done by placing the filling in one part of the capsule, which is then closed by sliding the other part over it. The closure can be additionally secured. The capsule should be made in such a way that it cannot be opened without damage, which prevents the contents from being tampered with, and for this purpose snap-on capsules are formed.

Soft capsules are one-piece and are available in different shapes. They have thicker casings than hard capsules. They can be formed, filled and closed during one manufacturing process, but the casings themselves can also be formed earlier. In addition, the casing material may contain an active substance. Liquids may be sealed in the capsules and the solids are usually dissolved or suspended beforehand to obtain a solution or suspension of paste consistency and placed in the capsule. The soft capsule casing is usually soft and flexible, but can also be hard. Soft capsules can be filled with solutions, suspensions and emulsions or pasty masses. These capsules are not suitable for filling with aqueous solutions, as this dissolves the capsule.

-

Is it possible to produce vegan or vegetarian supplements?

Yes, we produce supplements for vegans and vegetarians. All ingredients used in the product are properly certified and do not contain substances not permitted in the vegan or vegetarian diet. In addition, we use 100% vegetarian capsule in the production of the capsule. Such capsules are made from HPMC (hydroxypropylmethyl cellulose). HPMC may come from tree fibres or cotton fibres.

-

Where does capsule gelatin come from?

We have beef gelatine capsules (100% BSE free), pork gelatine capsules and fish gelatine capsules.

-

What are gastrointestinal capsules?

Intestinal capsules are delayed release capsules that are resistant to gastric juice. This type of capsules releases the active substance in the intestinal juice. They are usually made by filling the capsules with granules or particles that are coated with a gastric juice-resistant coating or, in certain cases, may be soft or hard capsules with a gastrointestinal casing.

-

What are extended release capsules?

Extended release capsules are modified release capsules. These are hard or soft capsules, the filling and/or casing of which contains special auxiliary substances or is prepared in a special way so as to modify the rate, place or time of release of the active substance.

Modified release capsules include: extended release capsules and delayed release capsules. -

What size capsules can you produce?

The most commonly used capsule size is "0". A "0" size capsule can hold a certain amount of substance. This depends on the type of filling. In the case of plant substances, it can hold a maximum of about 500 mg, and in the case of heavy minerals, about 600 mg.

In our offer we also have capsules in size "00", where the maximum amount of filling is about 800 mg, depending on the raw material, and capsules in size "000", where the maximum filling capacity is about 1.5 g, depending on the type of filling. We also have capsules 1, 2, 3, 4, 5, which we use mainly for probiotics. -

Is it possible to produce a colour capsule?

Yes, we are able to produce a product for the customer in coloured capsules. We determine the colours based on the pantone colour sampler. The minimum quantities of a coloured capsule are determined individually for a given type of capsule and its size. It is also possible to print on the capsules, e.g. company logo.

-

Must there be auxiliary substances in the capsule, if so what?

Yes, there are auxiliary substances in the capsules. There is a possibility to minimize the auxiliary substances used in the capsules, but all kinds of actions depend on the target composition of the product. The excipients that may be included in the capsule filling are, depending on the type of filling:

Solid excipients:

Filling excipients: mannitol, lactose, wheat starch, microcrystalline cellulose, pregelatinated maize starch, wheat starch. Excipients Sliding agents: magnesium stearate, stearic acid, glycerol monostearate.

Lubricating aids: colloidal silica, talc. Exploding aids: sodium croscarmellose, crospovidone, starch sodium glycolate, alginic acid.

Wetting aids: sodium lauryl sulphate, polyoxyethylene sorbitan monooleate.

Semi-solid or liquid excipients: Solvents: refined oils: peanut, castor, cotton, corn, sesame, soya, sunflower, olive oil; medium-chain triglycerides and their esters; Solubilizers, tensides, absorption promoters. -

Is it possible to order only confectioning services?

Yes, we accept orders only for packaging services, such as packaging, labelling, sleeving, spilling. Due to the fact that we have our own machine park, we are able to offer flexible minimum quantities of packaging services.

-

What are the sources of raw materials?

Laborell only works with raw material suppliers who meet our high quality requirements. Each individual raw material is thoroughly checked for compliance with the specifications. This principle applies not only to active ingredients, but also to excipients and packaging. Each supplier recommended by Laborell is verified for the quality of the raw materials offered. The raw materials are registered and marked with a unique number, so that it is easy to trace the path of the raw material throughout the production process.

-

What plant extracts can we use for production?

We use various types of plant extracts to produce supplements. Plant extracts are natural ingredients which, through their beneficial effect on the body, find a number of applications in the food, pharmaceutical and cosmetic industries.

Commercially available plant extracts differ in concentration with respect to the starting material (DER - dry extract ratio) and the level of standardisation for active substances such as: polyphenols, antioxidants, saponins, tannins, essential oils and others.

Popular extracts used in the production of food supplements are acai, acerola, Tagetes, aloe vera, blueberry, chlorella powder, hops, cinnamon, sage, thyme, Rhodiola rosea, Reynoutria japonica, camomile, Sabal palmetto, Morus alba , Linum usitatissimum, Foeniculum vulgare, Fenugreek, European olive, tomato, bitter orange, ashwagandha, Bacopa monnieri, black pepper, garcinia cambogia, guarana, hawthorn, green tea, ginger, purple coneflower(Echinacea purpurea), barley, green coffee, artichoke, pomegranate, St. John's wort, garlic, Chinese magnolia-vine (Schisandra chinensis), Tribulus terrestris , Beta vulgaris, bamboo, elderberry (Sambucus nigra), Valeriana officinalis, Tilia cordata, matzo, Silybum marianum, Curcuma longa, Pelargonium sidoides, Indian Coleus(Plectranthus barbatus), ginkgo biloba, dandelion( Taraxacum) , Fucus vesiculosus, sea- buckthorn (Hippophae rhamnoides) , rosemary, saffron, spirulina, Centella asiatica, Panax ginseng, soya, Rosa canina, Ruscus, cranberry.

-

What's the difference between probiotic and prebiotic?

Probiotics are lactic acid bacteria and prebiotics are substances that support the growth of their natural intestinal microflora. Popular prebiotics are inulin and fructooligosaccharides (FOS), which are found in wheat, garlic, onions and bananas. The best results are obtained by combining both groups. Preparations combining probiotics and prebiotics are called synbiotics.